Paper pulp packaging has grown to be a Main concentrate for businesses around the globe since they check here shift far from unsustainable components towards eco-welcoming answers. Molded pulp packaging provides a sustainable and cost-helpful way to supply high-good quality packaging that is certainly customizable and biodegradable. 1 place driving innovation is the introduction of substantial-efficiency pulp molding equipment, such as the Dwellpac Semi-Hotpress Machine. These machines support firms streamline creation even though ensuring precision and dependability.This information will check out The main element features of high-performance pulp molding devices, upkeep guidelines for lengthy-time period usage, approaches to cut fees even though maximizing output, And the way automation improves output and high-quality. Whether you happen to be a company operator or possibly a packaging Experienced, you are going to attain valuable insights to help improve your generation approach.

Table of contents:

Key options of substantial-performance Pulp Molding equipment

servicing guidelines for extensive-expression device overall performance

Price-conserving methods in creation

How Automation enhances Output and good quality

essential attributes of superior-Efficiency Pulp Molding devices

significant-performance pulp molding devices are revolutionizing how molded pulp producers run. The Dwellpac Semi-Hotpress equipment is 1 these types of example. It stands out for its Sophisticated Manage procedure, higher clamping precision, and seamless hydraulic functionality. With capabilities like precision shaping and eco-pleasant mildew pressing technological know-how, it makes sure that just about every eco-welcoming box packaging product is reliable in top quality and sturdiness. This is significant for industries needing tailored options like meals packaging, electronics, and industrial components. Such devices also aid a range of customized molded pulp packaging desires, presenting considerable flexibility in output.

servicing tricks for prolonged-phrase equipment Performance

keeping a pulp molding equipment is vital to making sure consistent output and maximizing its lifespan. standard upkeep responsibilities include cleansing the molding surfaces, inspecting hydraulic programs for dress in and tear, and making sure the Management procedure is up to date for peak functionality. The Dwellpac machine is made to simplify these procedures, enabling molded pulp companies to streamline maintenance. standard inspections and proactive treatment not just reduce unpredicted breakdowns but additionally assistance keep the precision criteria essential for high-good quality paper pulp packaging.

Cost-Saving procedures in generation

Expense-performance is a main problem for molded pulp producers. To save expenditures though sustaining top quality, they're able to enhance materials use by leveraging economical pulp mould pressing technologies to reduce waste, put money into Power-successful machinery just like the Dwellpac Semi-Hotpress equipment to reduce Electrical power consumption, and prepare workers to fully use Highly developed devices in order to avoid errors that produce inconsistencies or wastage. Moreover, purchasing eco-friendly products in bulk might help take advantage of lower prices and decrease overall creation fees. By adopting these techniques, suppliers can continue being competitive although providing significant-high quality, tailor made eco-helpful packaging to purchasers.

How Automation enhances Output and Quality

Automation happens to be a pivotal factor of contemporary generation procedures. Superior pulp molding equipment producers, including Dwellpac, integrate automation to reinforce operational efficiency. automatic units, by such as attributes like intuitive Command panels and true-time precision checking, lessen the probability of human glitches. This makes sure that every mold generated satisfies rigid quality expectations. With automation, businesses might also cope with large-scale output operates extra competently, meeting specific deadlines though developing molded fiber packaging at competitive rates. Also, the consistent quality achieved as a result of automation reinforces purchaser belief in eco-helpful packaging alternatives.

large-efficiency pulp molding devices are enabling firms to satisfy growing desire for sustainable packaging alternatives. By buying Innovative technologies, providers can make personalized molded paper pulp products that not merely guard the atmosphere but will also deliver remarkable performance and longevity. With revolutionary machines and thoughtful maintenance practices, corporations can prevail over manufacturing challenges, lessen operational prices, and provide eco-friendly products that cater to world-wide sustainability ambitions.

Tony Danza Then & Now!

Tony Danza Then & Now! Jeremy Miller Then & Now!

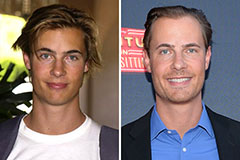

Jeremy Miller Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Michelle Trachtenberg Then & Now!

Michelle Trachtenberg Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now!